Automatic Train Operation has been a practical system for Metros for many years. Beginning with the Victoria line in London in 1969, ATO has become a normal means of operation for mass transit networks in most major cities. The technology has advanced down the years and more modern systems tend now to go under the acronym CBTC (Computer Based Train Control) which include many more features, often with provision for moving block. ATO yields much greater train throughput and enables significant capacity gains on the same infrastructure.

Yet, with capacity challenges dominating main line and suburban rail services, expansion of the ATO concept to main line rail operation has barely begun. Is it really that difficult? A joint seminar by the IMechE and IRSE was held recently in London to look at the issues.

The value of ATO

The seminar produced a whole range of speakers, from both infrastructure and rolling stock disciplines, with experience in the UK, Europe and across the world. It soon became evident that the requirements for main line ATO had a common theme, with everyone listing the same basic principles.

To get an efficient, practical and cost-effective ATO in place, the following elements would be needed:

- A proven ATP (Automatic Train Protection) system which would normally be ETCS Level 2;

- A bolt-on ATO package for automatic driving within the constraints of the protection system;

- A Traffic Management System (TMS) to analyse and regulate train movements for the most effective throughput;

- A C-DAS (Connected Driver Advisory System), interfaced with the ATO system, such that trains are driven at the optimum speed for timetable compliance and energy usage;

- The underpinning of all these by robust telecommunications, data and radio networks.

All these technologies currently exist, so why has industry not made greater efforts to bring them together into a single unified application?

As would be expected, there are many other factors that make this seemingly easy solution much more difficult

The European Standards dimension

The EU has been slow to realise the need but, in February 2016, main line ATO was added to the Command and Control System (CCS) TSI and a MoU (Memorandum of Understanding) was signed at InnoTrans for ATO to be included in the ERTMS documentation.

Wouter Malfait from the ERA (European Rail Agency) set out the objectives for ATO adoption. These are to increase capacity, safety, performance efficiency, punctuality and passenger comfort while, at the same time, decrease costs, energy consumption and rail noise pollution.

The vision is to have an open market where an independent on-board ATO interfaces with an independent ETCS train package. Train protection would be provided by the ATP, with safe driving entrusted to the ATO. In SIL terms this equates to SIL 4 and SIL 2 respectively.

Future challenges will be: the possibility of adopting ETCS Level 3, braking curve determination, the underpinning telecom network(s), GSM-R replacement and satellite tracking. Existing investments have to be protected and mandatory upgrades will need to be avoided unless absolutely essential.

Five work packages have been identified covering standardising the trackside information from TMS; a functional spec for the ETCS on board interfaces; determining human factors, release speed, audible and visual warnings; interfaces between ATO and ETCS for freight operation; and ATO requirements for driverless and unattended train operation. Wherever possible, these will be aligned with Shift2Rail work streams. Nothing will happen quickly, the non-safety related functions are to be set out by 2019 and there is no stated time for the rest.

International considerations

Several speakers informed delegates on what is happening internationally. David Dimmer from Thales in Canada told of the work to develop an ATO package for urban and main line use within the NGTC (Next Generation Train Control) project under the EU 7th Framework Programme. The analysis has compared CBTC and ETCS, where 49 per cent of functionality is similar but only one per cent at system level.

Eight work packages including moving block, IP-based radio, satellite positioning and message structure are underway. Train and platform door operation and train positioning will be quite different for main line ATO as compared to metro due to dis-similar operating conditions – metro trains typically stop every two minutes whereas main line stops are much more spread out. The coupling and uncoupling of trains also has to be considered.

Benoît Bienfait, the Intercity/ATO manager at Alstom, described the work to categorise the benefits of ATO. Current timetables allow for 90 per cent of trains to arrive early at stations. With ATO, the integration of infrastructure and timetable data will allow an optimum speed profile with guaranteed arrival and departure times. Energy savings of up to 12 per cent can be achieved compared to manual driving. Studies on different driver behaviour show a 15 per cent variance in energy consumption for inter-city trains and 40 per cent for local trains.

In Belgium, a need exists to increase the 92tph (trains per hour) through the six-track north – south junctions in Brussels where one free slot for every four trains is required to maintain stability. Studies show that ATO will help, but crucial will be the effective integration of data from lineside infrastructure, safe speeds under ETCS supervision including protection against movement authority overrides, accuracy of train position, plus TMS information on route, stopping pattern and arrival/departure times.

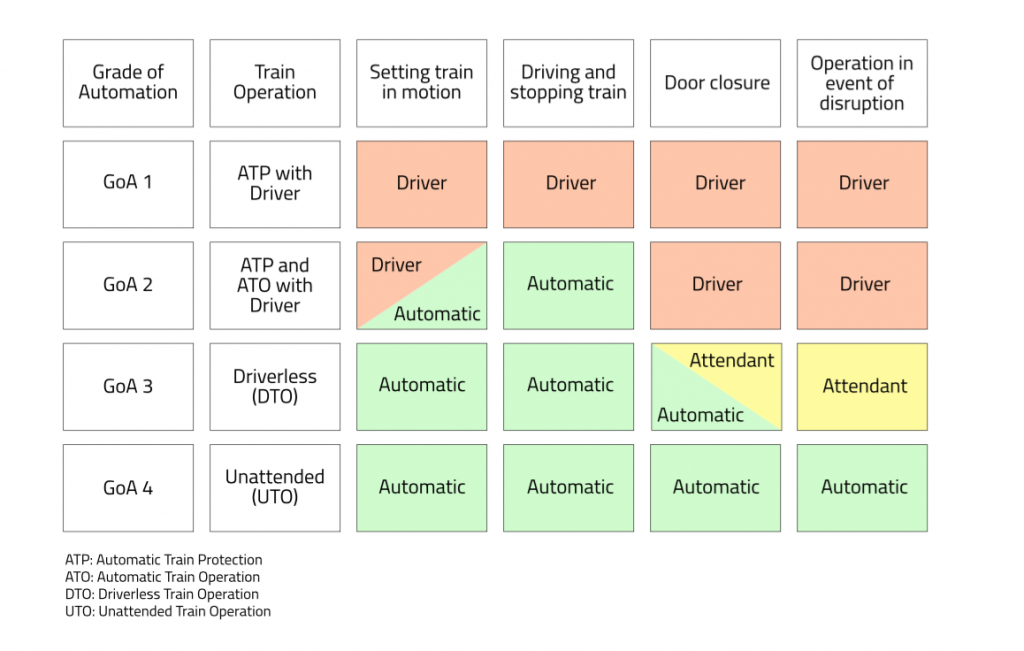

Ray Clifton from Siemens Rail Automation told of the company’s development plans for ATO on metro, main line passenger and freight requirements. The table (below) demonstrates the similarities and differences, and the step change in approach that will be needed both technically and operationally.

The Thameslink application (see later paragraph) will be watched closely in Europe as to how well ETCS and ATO can be integrated. The driver’s ETCS display might change in an ATO railway and communications channels both for data dissemination and radio links will need much greater capacity.

Some serious thinking on the holistic approach to ATO will be necessary according to Dr Xialou Rao from Systransis, as ATO cannot resolve traffic conflicts. How to evaluate the optimisation of capacity and the different optimisation intentions is a problem.

A Decision Support System with data from TMS, DAS and the intensity of traction and braking forces will be needed to produce an optimised train control trajectory. Its realisation will be dependent on constant bi-directional communications between TMS and the on board ATO equipment.

The British perspective

The capacity crunch caused by a doubling of passenger numbers since 1996 and continuing growth is well known. All this brings a demand for greater reliability and reduction in delay, so says Andrew Simmons from the Network Rail Digital Railway group. Solutions vary from ‘do nothing with reliance on road transport’ to conventional enhancements such as longer trains, the use of digital technology to enhance performance, major infrastructure work to widen existing routes, and building new lines.

Digital technology has already increased capacity on motorways by 20 per cent, on London Underground by 20 per cent and in air traffic control by 60 per cent. Applying similar technology to main line rail is a ‘no brainer’ and ATO has to be part of this.

Analysis work has been underway since 2007 but, in 2016, ATO was recognised as a game changer. Critical features such as timetable changes and optimising ETCS constraints are being modelled, with ATO seen as a closed-loop control system that will reduce the allowances built into train scheduling, allow closer running of trains and fine tune the regulations for train movements at conflict locations. The specifications for command and control elements, infrastructure changes and rolling stock traction and braking requirements will be issued by mid 2017.

Thameslink central core

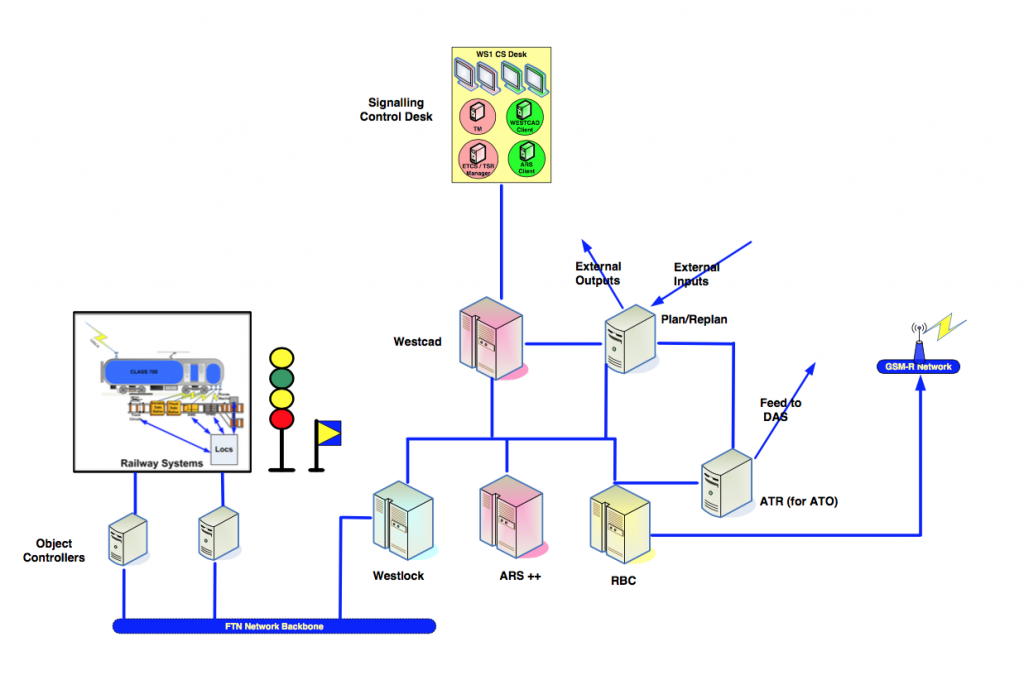

When the upgraded Thameslink opens in 2018, the throughput for the central London core will rise from 16 to 24tph in each direction with the flat junction at Blackfriars being critical. This is a train every 2.5 minutes and a headway of 150 secs. Jonathan Hayes, Network Rail’s engineering manager for integration, verification and validation on Thameslink, explained the elements required to achieve this. Block sections of 70 metres length, balises for stopping accuracy of ± 0.5 metres at stations with dwell times commensurate with 1,800 passengers per train, a revised ETCS protection curve, development of an ATR (Automatic Train Regulation) package plus TMS and C-DAS information are all needed. Only ATO can deliver the required train performance.

The signalling system being supplied by Siemens that includes the interlocking, ETCS and ATO is in the advanced testing stage. Modelled initially in a system integration laboratory, real testing has taken place on the ETCS National Integration Facility (ENIF) Hertford loop site and is now underway on the central core section during possession hours. Results are encouraging, but proof of repeatability and tests to validate the testing methodology are part of the process. The mass of data means that every test hour generates 4.6 hours of analysis. Thameslink is a main line railway that requires metro like performance.

A detailed update of the Thameslink scheme follows this article.

The London Underground experience

By pioneering ATO on metros, LU is probably more knowledgeable in ATO operation than any other organisation. Graham Neil, the head of rolling stock, described many other factors that need to be considered for an ATO project.

LU now has four lines equipped for ATO:

- Victoria line now re-equipped with a ‘distance to go’ radio system working on fixed block principles with a 34tph capability;

- Central line, equipped since 1997 with a 1992 design of ATO. Overground sections had to overcome problems of adhesion, staff access, trespassing and fencing;

- Jubilee and Northern lines using the Thales loop-based ‘Seltrac’ system as a full CBTC application including moving block. Low adhesion is a big problem and can lead to non-communicating trains with resort to manual driving.

LU retains a ‘train operator’ in the front cab for door control and train start command. Manual driving needs to happen on a periodic basis so as to retain familiarity. ATO brings great benefits but its limitation is that it cannot predict what might happen, so safe alternative arrangements need to be in place. In tunnel sections, where emergencies such as driver incapacitation, passenger alarm activation, a train fire and traction supply loss can occur, the system should always try and stop trains at a station and not in the tunnel.

Low adhesion during variable weather and climatic conditions (leaf fall) is the biggest problem for ATO systems, and LU is to appoint an adhesion controller when conditions demand it who will have knowledge of the high risk areas and instruct the train operators accordingly.

The new S Stock on the Metropolitan, District, Hammersmith & City and Circle lines will be fitted with sanding equipment to improve traction and braking. Data logging of all ATO commands and subsequent train performance is vital.

Rolling stock factors

Clearly, fitting trains with ATO equipment is crucial, but just how difficult will this be?

The ROSCO view, as expressed by Euan Smith from Angel Trains, outlined some of the factors that would have to be overcome. Different train compatibility, interworking between fleets, the need for a single type of coupler, and standards that would ensure everyone used the same protocols, will all be necessary. To achieve this, a systems authority might be required to plan the introduction programme. Trains typically have a life of 35 years, with four major upgrades in that time, and keeping the ATO technology current would need to fit with this cycle.

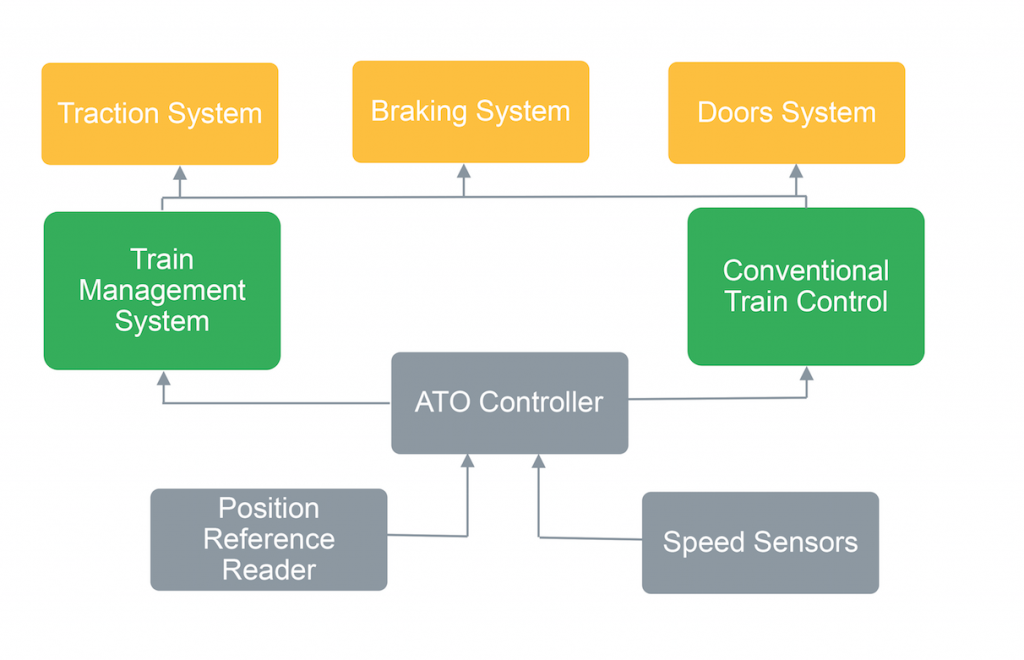

Jack Ratcliffe from Bombardier gave detail on train fitment challenges. Essential to effective ATO application would be:

- An accurate, installed train position reference system, be it bogie or body mounted;

- Speed sensing from axle sensors with a secondary back up system;

- Diverse speed indication by doppler radar, optical speed sensor or accelerometer;

- At least one speed probe on an unpowered axle; » Integration with doors and the train management system;

- 5-15 per cent tolerance of the demanded braking and traction rate;

- Control of regenerative and rheostatic brakes with no overshoot or undershoot;

- Fast reaction braking time plus blend out of speed and open loop braking;

- Efficient wheel slide protection and sanding;

- Load weight compensation for traction power with a slip limit of 5-10 per cent.

As a system, train testing will need to be both static and dynamic to prove auto driving, station stopping, position accuracy, door control and full integration with the infrastructure data including TMS. The communications link to the train is vital, including messaging to passengers.

Other factors will include keeping the railway clear of intruders, track-worker safety, vegetation control, management of the platform-train interface and the control of train despatch.

Transition to non-ATO areas without speed reduction has to be considered, with interfaces to ETCS, TPWS and AWS needing to be developed.

Freight interests

A plea from DB Cargo, the biggest freight operator in Europe, was made by Miroslav Obrenovic. With automation rapidly being adopted by the road sector – hands-free lorries are now being tested – something similar is needed for rail freight to cater for longer and heavier trains, noise and emission reduction plus energy and CO2 savings.

Digitisation is the first step with intelligent locomotives and wagons, all of which are being condition monitored and predictively maintained. Dispatching, fleet control and maintenance is well established. Automating hump shunting will begin within 12 months with real time management for coupling and train formation.

Migration to automatic right away on a green signal will begin trials in 2019 with already 800 locos equipped. Obstacle detection over a 400-metre distance with high precision stopping is already modelled.

The freight companies see automatic train operation as the future, whether this is integrated into other ATO systems or developed as an accessory to traditional signalling systems. Either way, it’s needed now!

Certifying the system

Like all new systems, main line ATO will need to go through an authorisation process before it can be used for public service. Richard Feasby from the National Certification Body (NCB) described what would be needed.

A fundamental element will be proving the inherent safety and the safety efficiency of the system. A 12-stage process is likely which must be independent of the suppliers. Underpinning it will be the Common Safety Method, ROGS and the Interoperability Regulations and each will need to be considered for the infrastructure, the rolling stock and the system as an entirety.

Due consideration will be taken of existing specifications and associated risk assessment and hazard analysis, also lessons from the metro and urban ATO applications and any cross acceptance of technology from other countries. Some new ATO specs for main line acceptance will have to be written.

The UK certification regime is mature with well- established protocols. There is a will to succeed but the skillsets need to be clear.

Summary

Did this seminar achieve its objectives? In broad terms, the answer is yes. It explored the benefits to be had by adopting ATO and the basic building blocks needed to establish ATO in operational terms, and it also exposed many of the challenges for both infrastructure and rolling stock that need to be taken into account. People will be better aware as to what is involved if a railway decides to progress an ATO scheme.

There are other issues which were barely touched on. First of these is industrial relations, since ATO will be a step change in how a railway is operated and this inevitably will have a big impact on the employed staff, not just drivers but other train crew and back-room controllers who have responsibility for dealing with emergency situations. The UK is only too well aware how difficult it can be to change working practices.

Another issue is the challenge of gluing together all the ATO components from a disparate supply base. The goal of having open standards is fine, but when collecting together the suppliers of ETCS (four main ones), ATO packages (maybe the same four but not necessarily the same one on a particular contract), TMS (at least four) and C-DAS (at least three) and you get a permutation of around 200 options.

Some elements – ETCS and maybe ATO – will already conform to interoperability standards but others – TMS and C-DAS – are proprietary systems with little commonality. The Thameslink project is manageable because it is small scale with limited supplier engagement where the necessary interfaces can be tightly controlled and tested.

ATO deployment will only make sense where capacity requirements are greatest, so perhaps the Thameslink model might be the sensible way forward as it restricts the amount of supplier competition into manageable combinations.

One questioner asked if ATO will drive trains in an optimised way. Evidence seems to exist that a skilled human driver can better the ATO performance. It was acknowledged that, in a minority of cases, this might be true. However, the consistency that ATO brings will give the greater benefit because all trains will behave in the same way, thus decision-making on regulation becomes much more certain.

Another question asked: “Where is the Directing Mind?” This was not properly answered but the specifications for both infrastructure and rolling stock are in preparation by the Digital Railway team. It is logical, therefore, that this group will lead the consensus of all parties and thus fulfil the role.

Well done the IMechE and IRSE for staging the event. At very least it has focussed minds and probably achieved much more than that.

Written by Clive Kessell.