Around lunchtime on Saturday 12 August, groundwater broke into one of two new high-speed rail tunnels under construction for German Railways (DB) just south of the German town of Rastatt, situated on the very busy Karlsruhe to Basel main line used by up to 200 freight and another 150+ passenger services daily – the busiest double track main line anywhere in Europe.

By sheer bad luck, the tunnel collapse happened at the only point the new 4.27km long tunnels cross under the existing line and significant earth movement on the surface resulted. The existing line suffered deformation for around 150 metres and had to be closed immediately. DB’s network planners had never expected such an event and, as a result, all the other routes from Germany to Switzerland were closed due to engineering and electrification work. So the only diversionary routes for up to 200 freight trains a day involved neighbouring France or a much longer route via Austria!

Credit: Google Maps.

Background

In September 1996, the Swiss and German governments signed an agreement in Locarno. Germany committed to providing more and better capacity for freight traffic destined for the then planned, now built, Lötschberg and Gotthard base tunnels under the Alps in Switzerland, which had been approved in 1992.

Reconstruction of the 182km section of main line from Karlsruhe to Basel on the eastern side of the Rhine in Germany into a four track railway, with 250km/h fast passenger lines and two more tracks for freight (and regional passenger trains), had been an objective for German Railways since the 1980s. However, despite the 1996 agreement with Switzerland, no new funding was provided by the German Government until 2003.

The Rotterdam to Genoa corridor – of which the line forms a major part, was identified as a priority by the EU in the 1980s. By 2017, several sections have been completed, others had construction agreed or underway, although the middle part of the route is still being hotly debated!

At the northern end of the Karlsruhe to Basel route, a new 16km two-track 250km/h line is being built to avoid the town of Rastatt, where the existing line has permanent speed restrictions caused by curves and junctions with multiple other lines at Rastatt station. It was the eastern bore of the new tunnels under Rastatt that suffered the collapse in mid-August 2017.

Project and financing

The new 16km long Rastatt avoiding line, designed for 250km/h operation, is under construction from just north of Durmersheim Nord on one of two existing lines from Karlsruhe to Rastatt with two new high speed tracks built to the east of the existing line parallel with the new B36 road (which was built in 2007). The northern ground alignment for the new railway was prepared at the same time as the new road was built.

The new line will then pass beneath the town of Rastatt in a new 4.27km twin-bore tunnel, which has been under construction using TBMs since May 2016 when work on the east (now damaged) bore began; work on the west bore began in September 2016.

The tunnels start just north of the town ending at Rastatt Süd (Rastatt South), around 5km north of the city of Baden Baden, where the new line will join the rebuilt four-track line to Offenburg, which has been in operation since 2004. Planning permission for the Rastatt avoiding line was granted in 1998 but the €693 million financing package was only agreed in 2012. The Rastatt avoiding line section was planned to open in 2022 although, with the delay caused by the tunnel collapse, this is now in doubt.

SBB Cargo Class 482 TRAXX locos haul a freight train over the route in September, 2016.

Tunnelling

The tunnels are being constructed at a cost of €312 million by special purpose organisation Arbeitsgemeinschaft (ARGE) TunnelRastatt comprising technical tunnelling specialism provided by Stuttgart-based Ed.Züblin AG (owned by Austrian civil engineering group Strabag) and overall project management provided by German civil engineering firm Hochtief AG. Herrenknecht supplied the two TBMs to ARGE TunnelRastatt for the project. German national rail infrastructure manager DB Netze is the customer.

Geology

The tunnels are being built in sedimentary rock that is geologically ‘recent’. The strata consists of Tertiary and more recent Quaternary sediments and alluvial deposits (sand, silt and gravel based) – the top layers of which were left as the glaciers retreated at the end of the most recent Ice Age which, along with the river itself, created the flat, wide Rhine valley between the Black Forest on the German side and the Vosges mountains in France.

The Rhine is around seven kilometres west from Rastatt and underground rivers flowing into the Rhine are a feature of the local geology, as is the presence of ground water, especially in the sandy sediments where it is found up to 10 metres below ground.

DB and its engineers are very experienced in tunnel construction in sandy areas where there is a high water table – much of the work undertaken since German re-unification in Berlin (including Berlin Hauptbahnhof) has been in similar conditions.

Tunnelling approach

Due to the local geology and the presence of groundwater and underground rivers, the tunnel’s builders had opted for TBMs rather than other methods. To enable the TBM to operate in the area, and in locations where it would be running close to the surface, the ground to be tunnelled through was being stabilised in advance of the TBM by being frozen, using either brine or liquid nitrogen, and injected with cement-based grouting prior to tunnelling.

The TBMs utilise a mixed shield – part of which is pressurised and which can withstand groundwater in the rock being excavated to a pressure of 15 Bar. Ground freezing and sprayed shotcrete concrete is being used to excavate the cross passages between the two tunnel tubes.

Watertight concrete troughs, built in 2014/2015, form cuttings 800 and 895 metres long at either end of the tunnel being built by the TBMs; the work at both ends involved open excavation and construction, some of it underwater due to ground water levels. The concrete troughs /cuttings are designed to prevent groundwater flooding into the completed tunnel at either portal – from their mass and length they are designed to exert enough pressure on any water present to retain it in surrounding soil and rock rather than entering the tunnels.

Tunnel technicalities:

- TBMs – Herrenknecht Mixed Shield machines S-953 “Wilhelmine” and S-954 “Sibylla-Augusta”;

- Power rating – TBM 4,500kW, cutter head 1,920kW;

- Weight – 2,300 tonnes;

- Length – 93 metres;

- Cost – €36 million (two TBMs);

- Outer diameter – cutter head 10.94 metres;

- Inner diameter (completed tunnel) – 9.6 metres;

- Concrete segments – Seven two-metre-long concrete segments per ring of tunnel lining; 30,000 in total (both tubes);

- Tunnel length – 4.27km;

- Tunnel depth below ground – max 20 metres, min 4 metres;

- Two bores – connected by eight emergency cross passages every 500 metres;

- Material to be excavated and processed – 710,000 cubic metres;

- Tunnel construction railway – 900mm gauge with seven works locos (Schöma CFL180DCL/ CFL200DCL) and one Schöma CEL60 battery loco for rescue train.

The collapse and aftermath

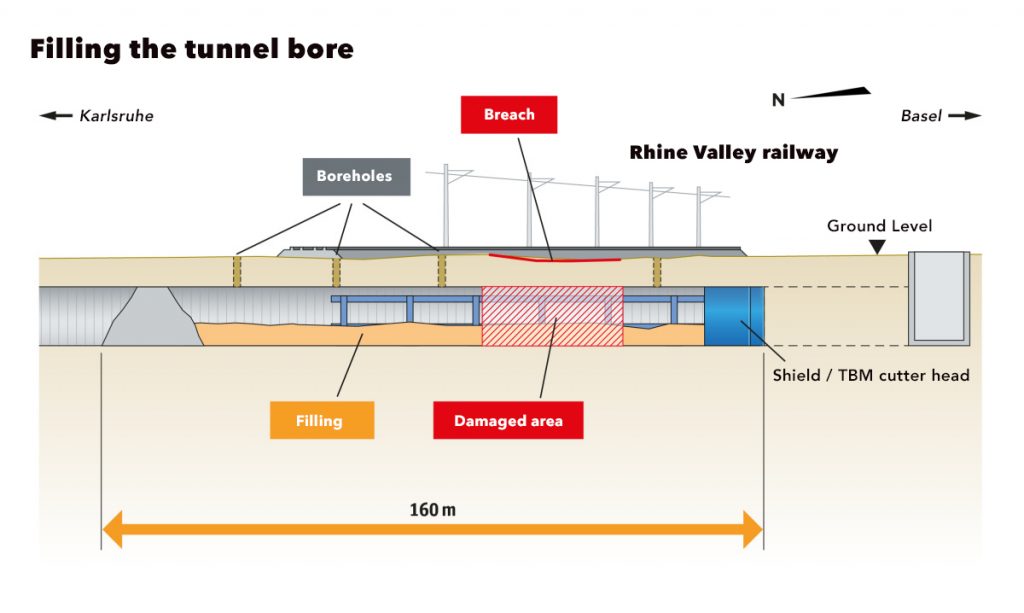

The new tunnel section that collapsed was around 50 metres long and the collapse occurred after water entered the eastern bore just behind the TBM shield /cutter head and caused a section of the newly constructed but not yet fully lined tunnel to fail. Nobody was injured and remote sensors above ground detected the collapse which led to signals being set to danger on the railway line above – by good fortune no train was passing as the hole opened up under the track! The front of the TBM itself was actually approximately 50 metres beyond the location of the main damage above-ground.

The section which failed was only around five metres deep at the point of collapse, leading to major earth movement on the surface which, in turn, lead to serious deformation of a 150-metre long section of the main line railway directly above the void where the tunnel had been.

Stabilisierung der Rheintalbahn in Rastatt/Niederbühl – Verfüllen der Tunnelröhre

Immediate response

From 12 August onwards, DB Netze with its contractors undertook work to stabilise the underground construction site. The void under the track was filled with concrete to plug the tunnel and protect the nearly four kilometres of completed tunnel to the north. To minimise risk to local inhabitants, some were initially required to leave their homes near the tunnel construction site. A 160-metre long section from the plug to the TBM was then filled with 10,500 cubic metres of concrete; an operation that took 150 hours of continuous concrete pouring and was completed on 25 August.

Initial assessment of the damage suggested that the ground-freezing system failed for the section under the existing railway. What caused this has yet to be confirmed, although hot summer weather, coupled with heavy rain, has been suggested as the likely cause.

Preparing for reinstatement

Once the site was stabilised, DB Netze had to quickly plan and organise how to reopen the railway and enable the tunnel construction to be completed. A section of the existing main line was removed – around 2,500 tonnes of ballast and earth plus all rails, 400 sleepers and OLE equipment.

DB then constructed a 120-metre long, 15-metre wide, one-metre deep concrete slab on which to place the existing ground level railway. This will act, effectively, as a bridge over the eastern bore tunnel route, so stabilising the site and allowing the reopening of the railway above despite the damaged tunnel remaining underneath. This required 1,100 cubic metres of concrete delivered in 130 truckloads to the site.

Despite the precise cause of the August failure not yet being established, DB has decided to take no chances with a repeat of the August incident and a second, similar slab will be built 150 metres north to cover the area where the western bore will pass under the railway. Having been paused after the 12 August incident, tunnelling for the western bore resumed during the first week of September. At that point, it was around 800 metres north of the point it will cross under the existing railway – it was expected to pass underneath before Christmas 2017.

After the two slabs have cured, the railway will be rebuilt on top of them, enabling the line to re-open. Initially, in mid-August, DB had suggested the closure might be around two weeks but, ten days after the collapse, announced that the line will re-open on 2 October 2017.

The eastern bore TBM is actually around 50 metres beyond where the main damage above ground is, and it is planned to recover the remains of the TBM (entombed in concrete) by digging it out of the ground. How construction of the final section of the eastern bore will continue remains unclear. The section remaining unbuilt of the eastern tube is less than 500 metres – although 160 metres of this is now filled with concrete.

Impact on rail operations

The existing main line railway above the tunnel workings was closed to all rail traffic on 12 August. Immediately after the incident, DB said it would offer alternate paths and routes to the 200-or-so freight trains routed via Rastatt daily and would consider the use of road transport on parallel motorways or shipping some freight on the River Rhine where viable.

DB’s immediate options to divert freight traffic on its own network were, in fact, severely limited by existing pre-planned closures on both of the other electrified routes from Germany to Switzerland and parts of the non electrified route via Lindau – all for engineering work.

Some of this work was curtailed once the scale of the Rastatt problem became clear; the electrified Stuttgart-Singen-Schaffhausen route being made available in early September – sooner than previously planned. Initially, in mid-August, DB had suggested the closure might be around two weeks but, ten days after the collapse, announced that the line would remain shut for weeks; with 2 October 2017 finally confirmed as the reopening date.

Rail freight operators, trade bodies and customers have been highly critical of both the DB response and the tardy offers of neighbouring countries’ railways to assist. The low availability of train paths – especially in France, which also has a two-track electrified main line on the other side of the Rhine – led to major delays for many shippers.

After several weeks, Swiss Railways (SBB) announced in early September it had agreement to use its own French-speaking drivers in France, although the number permitted to operate there was limited.

The majority of freight trains on the Karlsruhe-Basel route are operated by modern Bombardier Traxx or Siemens Eurosprinter/Vectron locomotives. Whilst some Traxx can operate in France, many of those in regular use between Germany and Switzerland may not be fitted with the necessary French safety and signalling systems. Siemens Eurosprinter/Vectron locomotives are not approved for use in France.

SBB, working together with DB Cargo, introduced a freight shuttle service linking the major marshalling yards in Stuttgart and Zürich and, by mid September, announced they would operate up to 116 trains on this corridor daily; up from 62 a day at the beginning of September.

Many rail freight operators and shippers have stated their intention to seek compensation for business lost due to the closure of the line from both DB and, potentially, the German government. Private rail freight operators and customers have also questioned why DB could not have built a temporary, single-track diversionary route, enabling freight trains to pass the tunnel collapse site at slow speed; it doesn’t appear that DB ever seriously considered this option.

Serious questions have also been raised at EU level about the lack of suitable diversionary routes and the lack of adequate cooperation between neighbouring national railway infrastructure managers.

This article was written by Keith Fender.